|

|

SYSTEM COMPONENTS

|

Cartoning Machines

Cartoning Machines can be used to create a box or an envelope around a stack of products. These machines automatically erect a box that can be filled on a system. Cartoning machines can be run with intermittent or continuous motion. Multifeeder Technology® can feed your product directly into in-feed buckets on a Cartoning system, or count and drop stacks of product using an ADT (Automatic Drop Table).

|

|

Wrapping Machines

Wrapping Machines can be used to automatically wrap plastic around a product, or a stack of products. These machines include intermittent motion L-Bar sealing machines and semi-automatic L-bar sealing machines, in addition to faster computer-controlled machines. Some wrapping machines have belted in-feeds, whereas others have flighted in-feeds to carry one product at a time, or stacks of products to be wrapped. The products can then be passed through a shrink tunnel onto a Shingling conveyor to be accumulated for Pack off.

|

|

Automatic Gluing Machines

The Automatic Gluing Machine can be used to apply glue to a package as it passes in front of the glue machine. Some glue machines have the ability to apply cold glues (such as latex glues), and some glue machines apply hot melt glue. The types of glue that can be applied include permanent or fugitive glue, which allows the glued product to be removed without damage. Multifeeder Technology Inc. has the capability to interface with a wide variety of different glue machines to create a Tipping system to meet your needs.

A Multifeeder feeder can feed a base sheet, and a Glue machine can be used to apply glue to the base sheet. A second Multifeeder Technology® Friction Feeder can be used to feed another product into the pinch point of a Pressure Roller Assembly to assure proper placement of the insert.

|

|

Inkjet Machines

An Inkjet machine can be used to apply a lot or date code directly to a product automatically as it passes in front the of the inkjet machine. MFT Series Friction Feeders can be used to present product under an inkjet machine to add printed material as the product is fed. The discharge section on the MFT Series Friction Feeder provides a stable work surface to present products to be inkjet printed. An inkjet machine can be mounted directly to the discharge section of the feeder, or the feeder can feed the product onto a conveyor to be printed. Typical applications include lot codes, date codes, product name, etc.

|

|

Labeling Machines

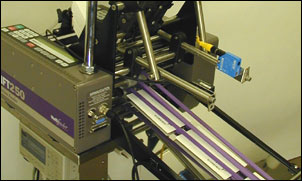

A labeling machine can be used to apply a label from a roll onto a product as it is fed. Labeling machines can work intermittent motion - applying a label when the product is in a stopped position (stamp on Label) - or they can apply a label to a product while it is moving (wipe on Label). The discharge section on the MFT Series Friction Feeder provides a stable work surface to present products to be labeled. A Labeling machine can be mounted directly to the discharge section of the feeder or the feeder can feed the product onto a conveyor to be labeled. An LSI model 316 labeling machine is shown. To learn more about LSI, please visit labelingsystems.com/.

|

|

Bar Code Readers

A Bar Code Reader System can be used to verify the bar code of a product as it is fed. MFT Series Friction Feeders can be used to present products under a bar code reader to be verified.

A Bar code reader system can be integrated with an MFT Friction Feeder to signal the feeder to stop and display an error message if a "No Read" or "Bad Read" occurs. The discharge section on the MFT Series Friction Feeder provides a stable work surface to present products to be verified. A Bar Code Reader System can be mounted directly to the discharge section of the feeder or the feeder can feed the products onto a conveyor to be verified.

|

|

Vision System

A vision system can be used to compare a product to known good product to ensure the correct printing is observed on a leaflet or that the product is the correct size and color.

Vision systems can be integrated with an MFT Friction Feeder to signal the feeder to stop and display an error message if a defect is found. The discharge section on the MFT Series Friction Feeder provides a stable work surface to present products to be verified. The Vision System can be mounted directly to the discharge section of the feeder or the feeder can feed the products onto a conveyor to be verified.

|

|

|